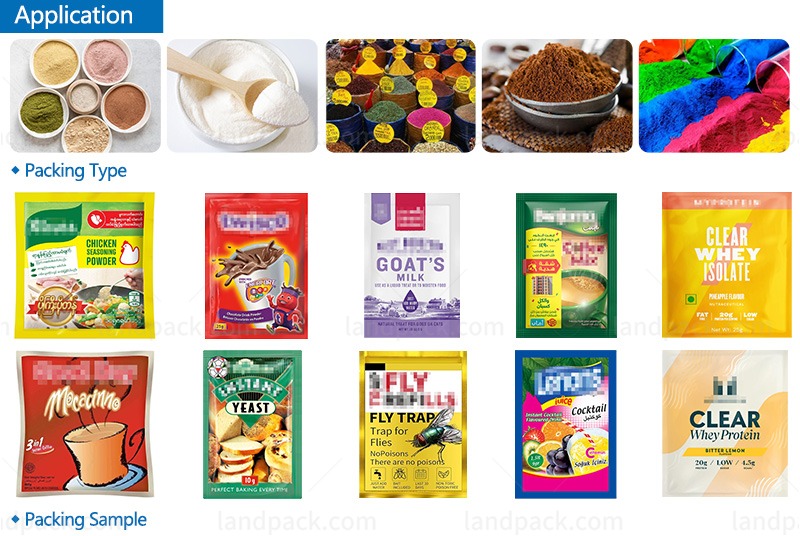

Application:

This Powder Sachet Packaging Machine is extensively utilized by industries that demand fast multi-lane packaging of fine powders or Granules. It can accommodate a variety of sachet formats like 3-side seal as well as 4-side seals and stick packs. This makes it suitable for packaging items for food, beverages as well as pharmaceutical, nutrition and everyday Chemical production lines. With exact filling accuracy and reliable sealing capabilities, it guarantees the same quality of product and increases efficiency in production.

Applicable Bag Types:

The multi lane packing machine is specially designed for high-speed production of small sachets and is compatible with various pouch styles to meet different product and market needs.

Applicable Products:

Landpack multi-lane powder packing machine was specifically designed to provide high-efficiency packaging for many different powders used in the health, food, as well as chemical industries.

* Food Powder: Suitable for kinds of beverages and food powders, such as milk powder, coffee powder, cocoa powder, seasoning powder, baking powder, and more.

* Nutrition & Health Powder: Widely used in the fitness and nutritional supplement industries for collagen powder, protein powder, vitamin powder and mineral supplement powders that provide exact control of portions for customer comfort.

* Other Industrial Applications: Also suitable for non-food powders including herbal powder, chemical agents powder, prescription powder, detergent powder, and washing powder, offering flexible solutions for both pharmaceutical and industrial packaging needs.

With its multi-lane, high-speed operation, this machine can produce multiple sachets simultaneously, making it an ideal solution for the mass production of small powder pouches in industries that demand hygiene, accuracy, and efficiency.

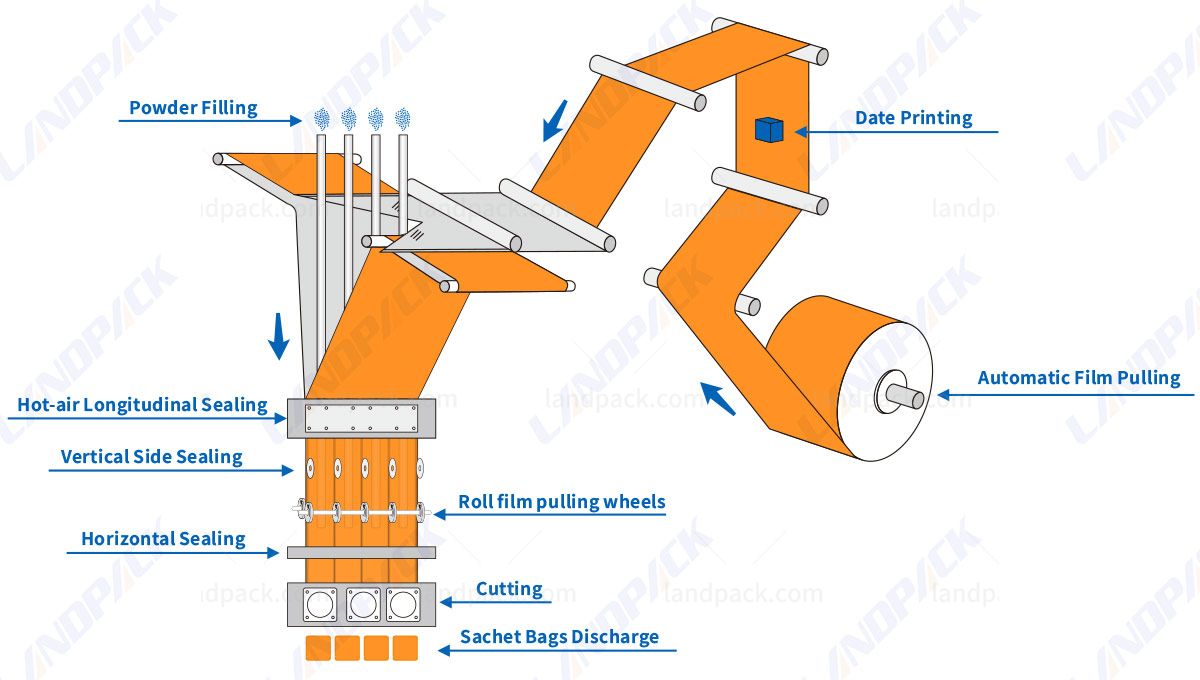

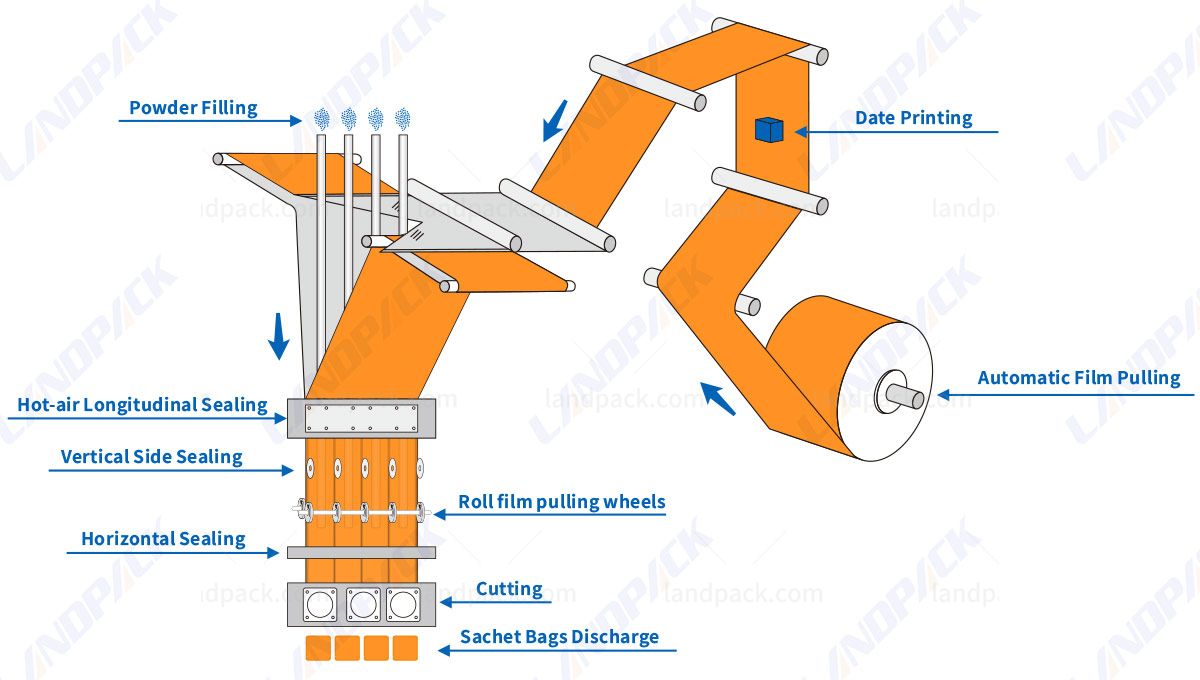

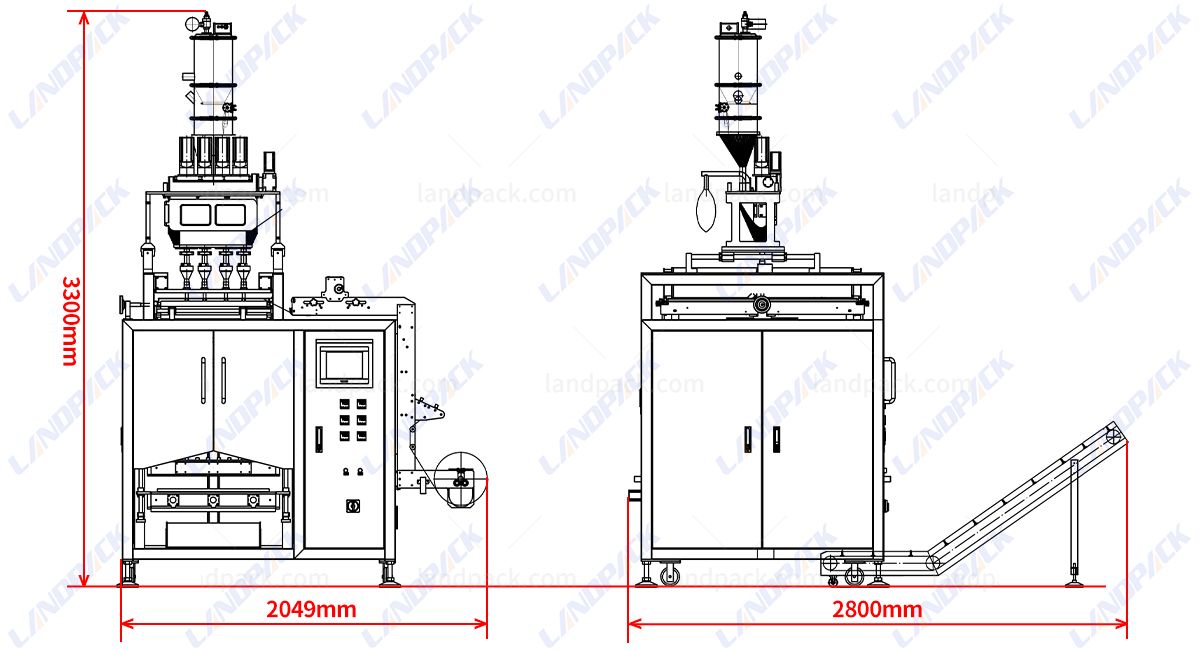

Workflow:

This multi lane sachet packaging machine is perfect for beverages, food, pharma, and other powder products. Here's how it works step-by-step:

* Automatic Film Pulling: The film roll is automatically pulled and fed into the machine smoothly, ensuring stable and continuous operation.

* Date Printing: A date printer marks each sachet with important production information such as batch number or expiry date.

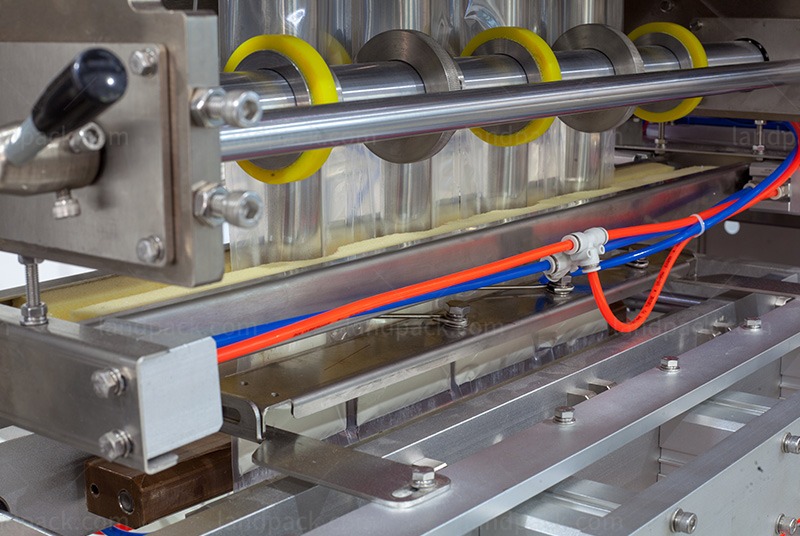

* Roll Film Pulling Wheels: The film passes through pulling wheels that maintain precise tension and alignment for accurate bag forming.

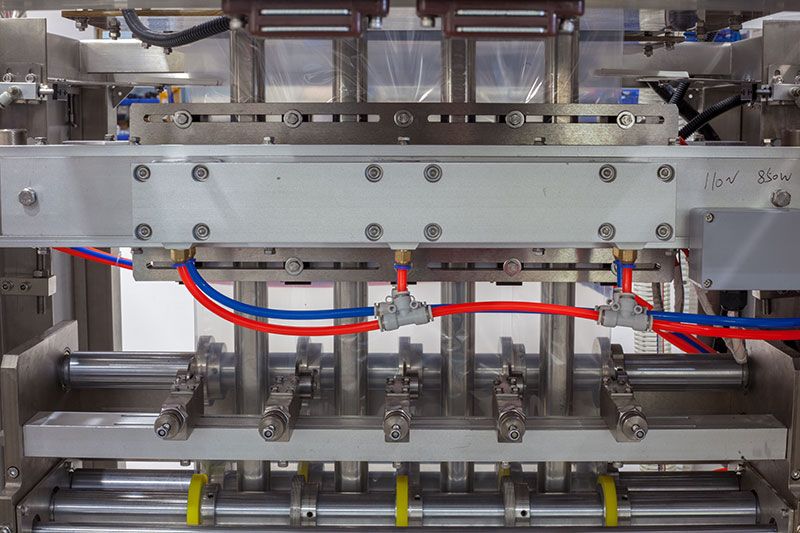

* Powder Filling: The powder that is measured is accurately incorporated into each sachet using dosing nozzles, which ensures an even weight.

* Hot-Air Longitudinal Sealing: The film edges are sealed vertically with hot air to form the main body of the sachet.

* Vertical Side Sealing: The side edges of the sachets are tightly sealed to prevent from leaking and maintain a clean appearance.

* Horizontal Sealing: The edges at the top and bottom of each sachet are sealed to create completely enclosed packets.

* Cutting: This continuous sachet strip are divided into pouches that are cut with exact alignment.

* Sachet Bags Discharge: The finished sachets are neatly discharged from the machine, ready for secondary packing or boxing.