Application:

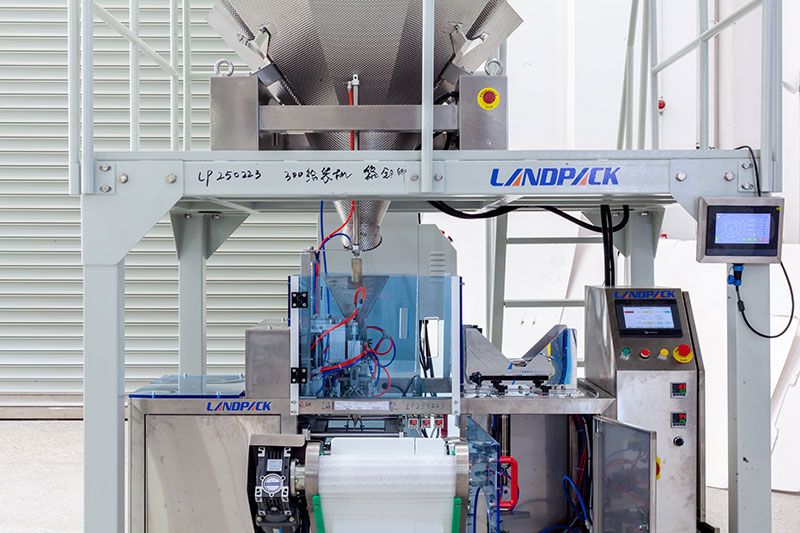

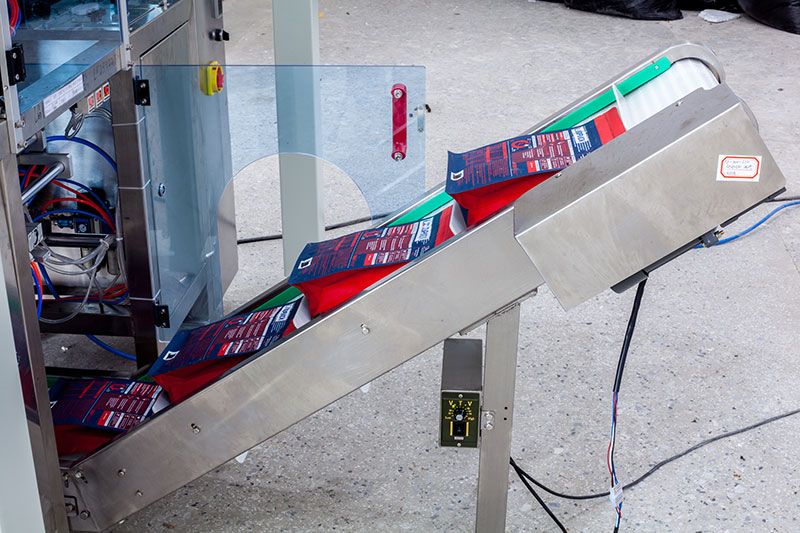

This mini doypack packaging machine is ideal for single-station premade bag packaging of gummy candies, chocolates, hard candies, and various sweets. It handles stand-up pouches, zipper bags, and flat pouches, seamlessly integrating automatic bag feeding, precise weighing, filling, and sealing into one compact, efficient system.

Package Type:

The Mini Doypack Packing Machine is designed to work with a wide range of premade pouches, offering great flexibility for different packaging styles. It is compatible with stand up pouches, flat pouches, and M shape/gusset pouches to increase volume capacity. It also perfectly handles standard doypacks and other premade pouches with or without zipper.

Suitable Products:

This mini doypack machine with multihead weigher is ideal for accurately and efficiently packaging a wide range of products. It is perfectly suited for food items like nuts, candies, snacks, frozen foods, and grains, as well as non-food items such as hardware components and plastic parts.

-Snack & Confectionery Products: gummies, popcorn, corn chips, chocolate, biscuits.

-Nuts, Seeds & Dried Fruits: almonds, cashews, peanuts, sunflower seeds, banana chips, dried apricots.

-Grains, Cereals & Frozen Foods: rice, coffee beans, peas, oats, pasta, frozen snacks.

-Non-Food & Industrial Products: pet food, fish feed, hardware, rubber parts, detergent powders

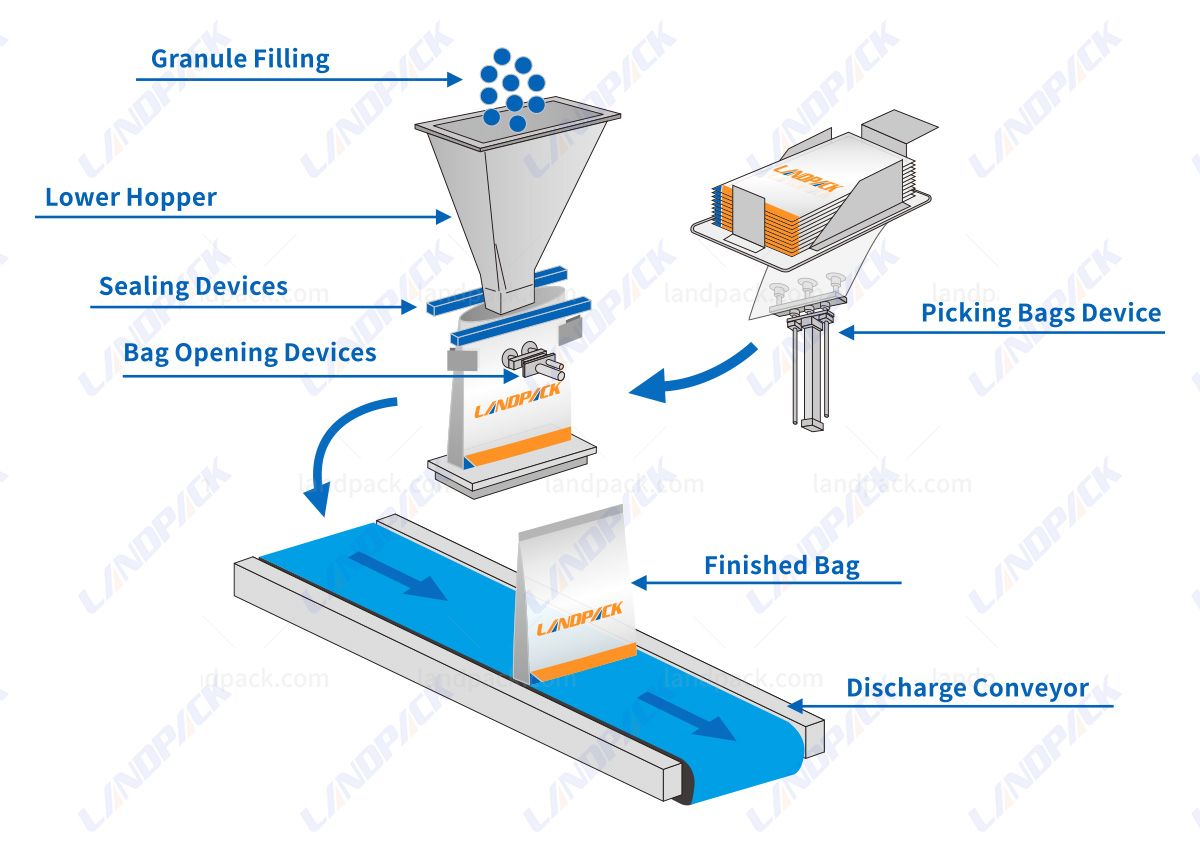

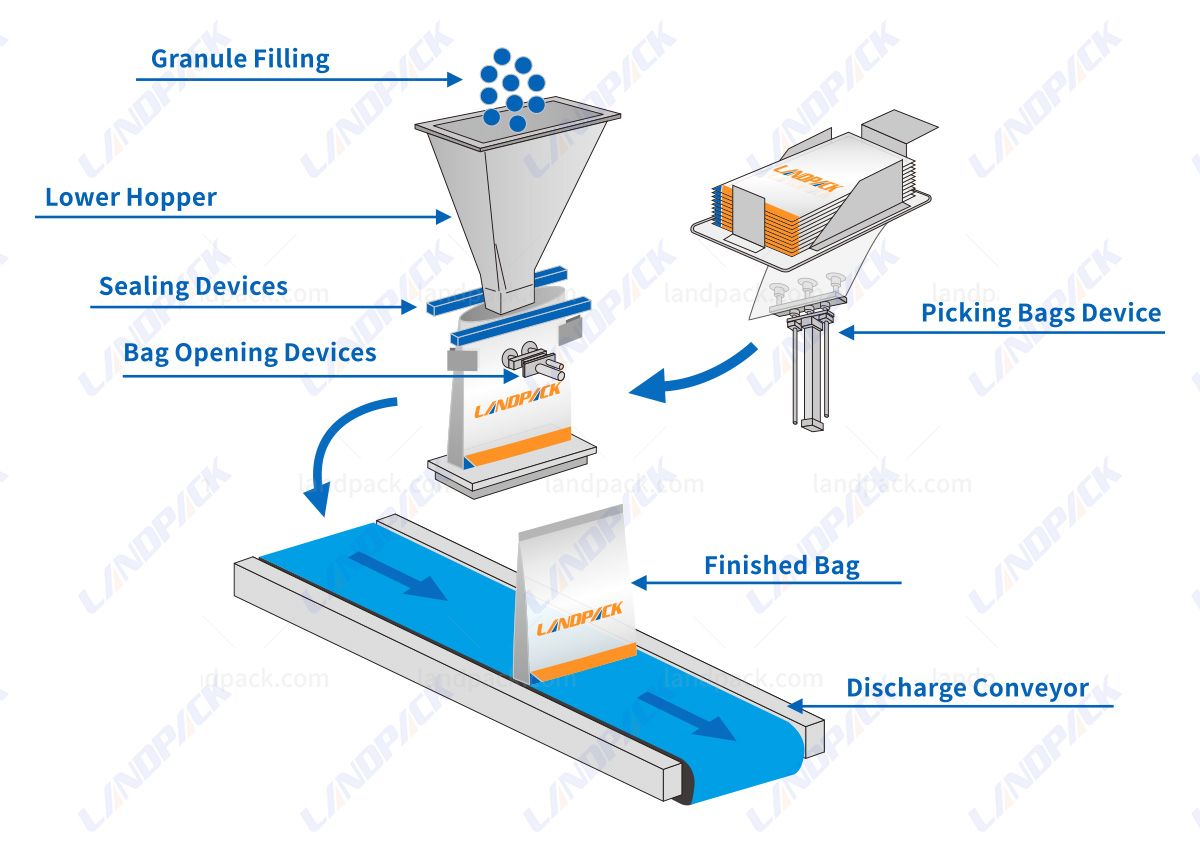

Workflow:

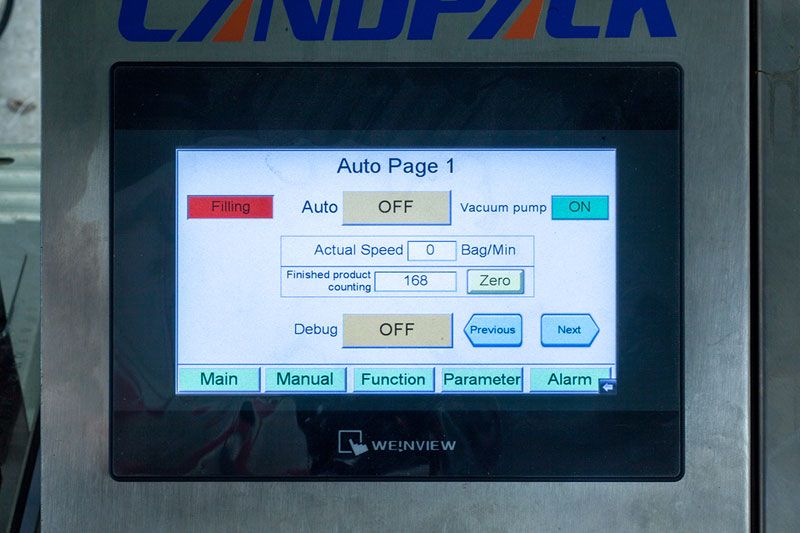

The working process of the Mini Doypack Packaging Machine is simple and efficient:

1. Picking Bags: The machine automatically selects each pouch from the magazine of the bag.

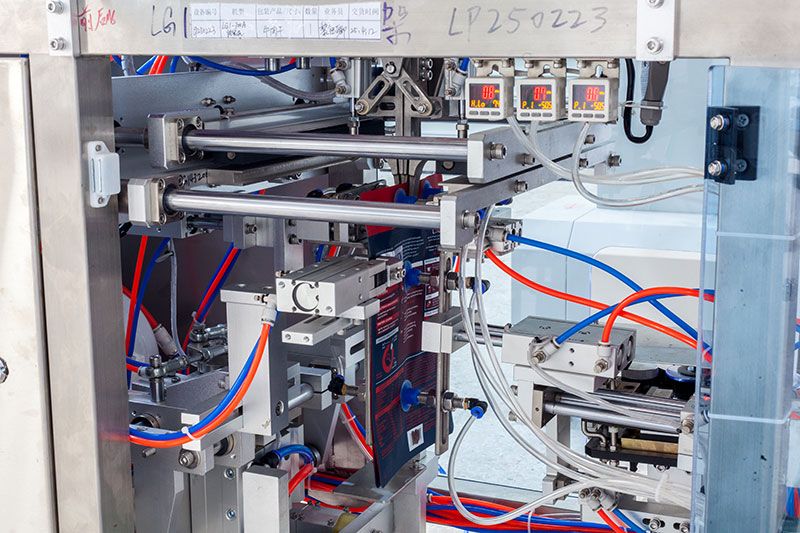

2. Bag Opening: Air blasts or mechanical arms can open the bag to make it ready for filling.

3. Granule Filling: Granules (such as jerky, beans, nuts, and more) are precisely dispensed inside the bag once it has been opened.

4. Lower Hopper: The hopper is lowered gently to guarantee the smooth and neat filling of the product without spills.

5. Sealing: Sealed tightly bag's top to ensure that the product remains fresh and safe.

6. Completed Bag Output: The sealed pouch is discharged on the conveyor and is ready to be secondary packed or delivered.