Application:

High-Speed Rotary Pouch Packer for precise and efficient premade pouch packaging. Specifically excels in handling a wide range of confectionery products, including gummies and other candies, alongside food, pet food, frozen goods, chemicals, and pharmaceuticals. Achieves speeds of up to 60 bags/min.

Package Type:

Various bag types are available: All type of heat sealable performed side seal bags, block bottom, bags,zip-lock recloseable bags, stand-up pouch with or without spout, paper bags, etc. With resealable and display-friendly designs, they are widely used for food, beverages, daily products, pet food, and industrial goods.

Suitable Products:

This mini doypack machine with a multihead weigher is ideal for accurately and efficiently packaging a wide range of products. It is perfectly suited for food items like nuts, candies, snacks, frozen foods, and grains, as well as non-food items such as hardware components and plastic parts.

-Snack & Confectionery Products: gummies, biscuits, corn chips, chocolate, energy bites.

-Nuts, Seeds & Dried Fruits: pumpkin seeds, cashews, peanuts, sunflower seeds, banana chips, dried apricots.

-Grains, Cereals & Frozen Foods: frozen fruits, coffee beans, peas, oats, pasta, frozen snacks.

-Non-Food & Industrial Products: pet food, fish feed, hardware, rubber parts, detergent powders

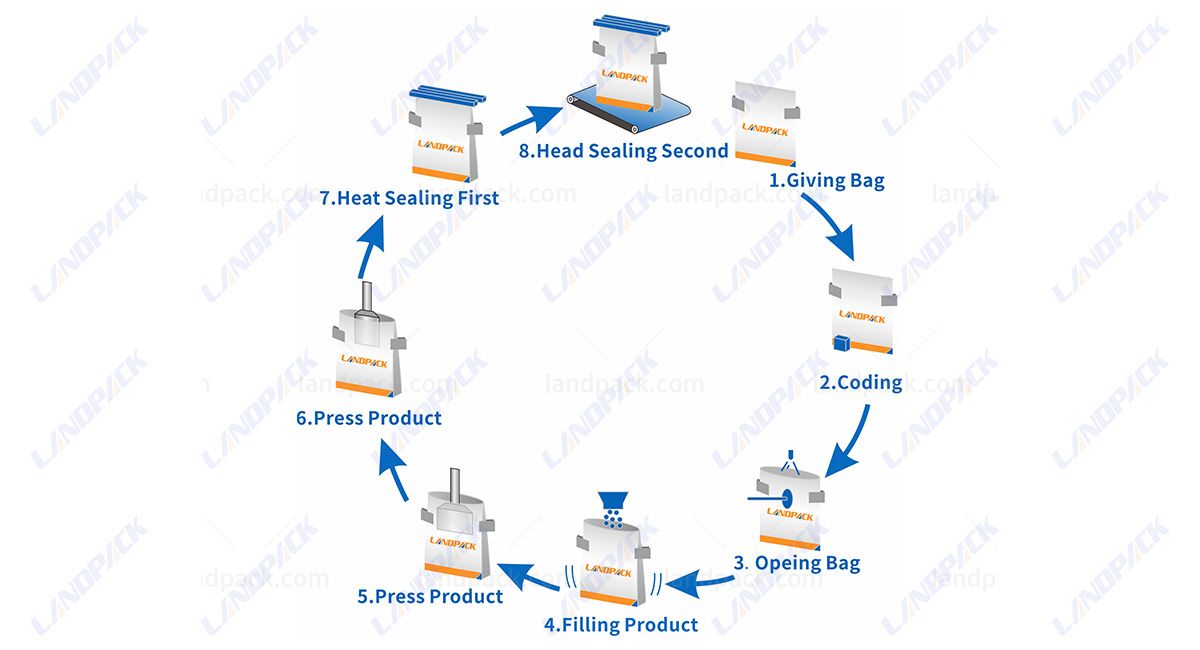

Workflow:

1. Bag Giving – The premade pouch is delivered to the machine.

2. Coding – The pouch is marked with date, batch code, or other information.

3. Bag Opening – The machine opens the pouch for filling.

4. Filling Product – The target product (powder, granules, liquid, or snacks) is filled into the pouch.

5. First Pressing – The pouch is pressed to settle the product inside.

6. Second Pressing – Ensures the product is evenly positioned for sealing.

7. First Heat Sealing – The pouch is sealed securely with heat.

8. Second Heat Sealing – This seal is reinforced to provide extra protection, assuring the package is airtight as well as secure.