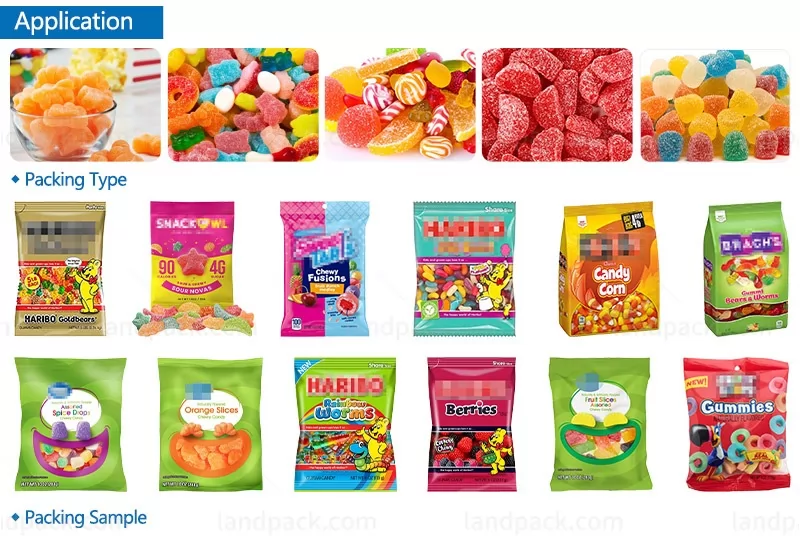

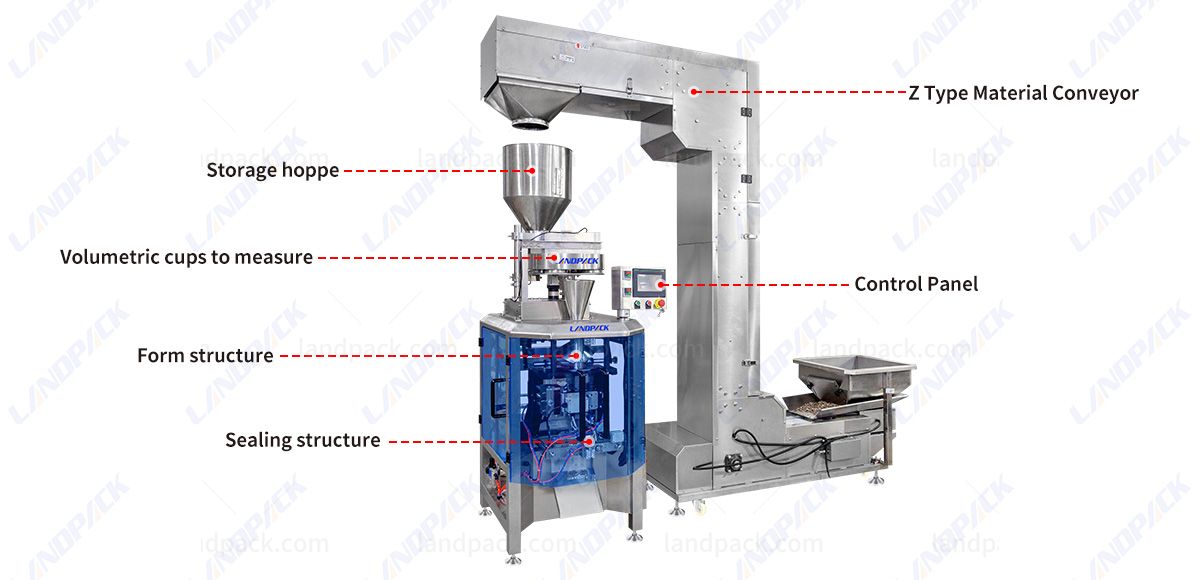

Application:

Maximize your production with our High Speed Gummy Packing Machine With Measuring Cups Equipment. Engineered for precision and speed, this robust system is the essential upgrade your confectionery operation needs.

Package Type:

The integrated vertical form fill seal (VFFS) mechanism expertly handles rolls of film to create the following bag formats: Pillow Bags (Standard Bag), Gusseted Bags, Quad Seal Bags (Flat Bottom Bags), Stick Packs/Sachet Bags, etc.

Suitable Products:

Our High Speed Gummy Packing Machine is extremely versatile and was designed to handle a wide range of goods from many industries.

-Snack & Confectionery Products: gummies, popcorn, corn chips, chocolate, biscuits.

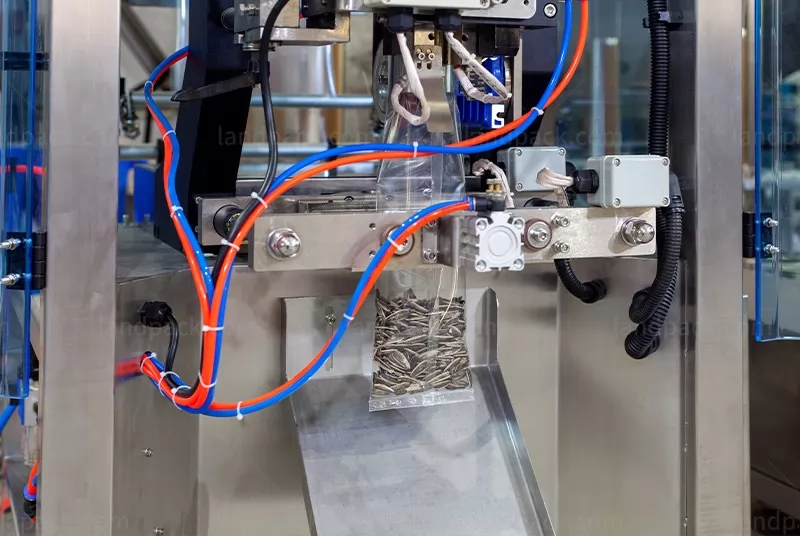

-Nuts, Seeds & Dried Fruits: almonds, cashews, peanuts, sunflower seeds, banana chips, dried apricots.

-Grains, Cereals & Frozen Foods: rice, coffee beans, peas, oats, pasta, frozen snacks.

-Non-Food & Industrial Products: pet food, fish feed, hardware, rubber parts, detergent powders

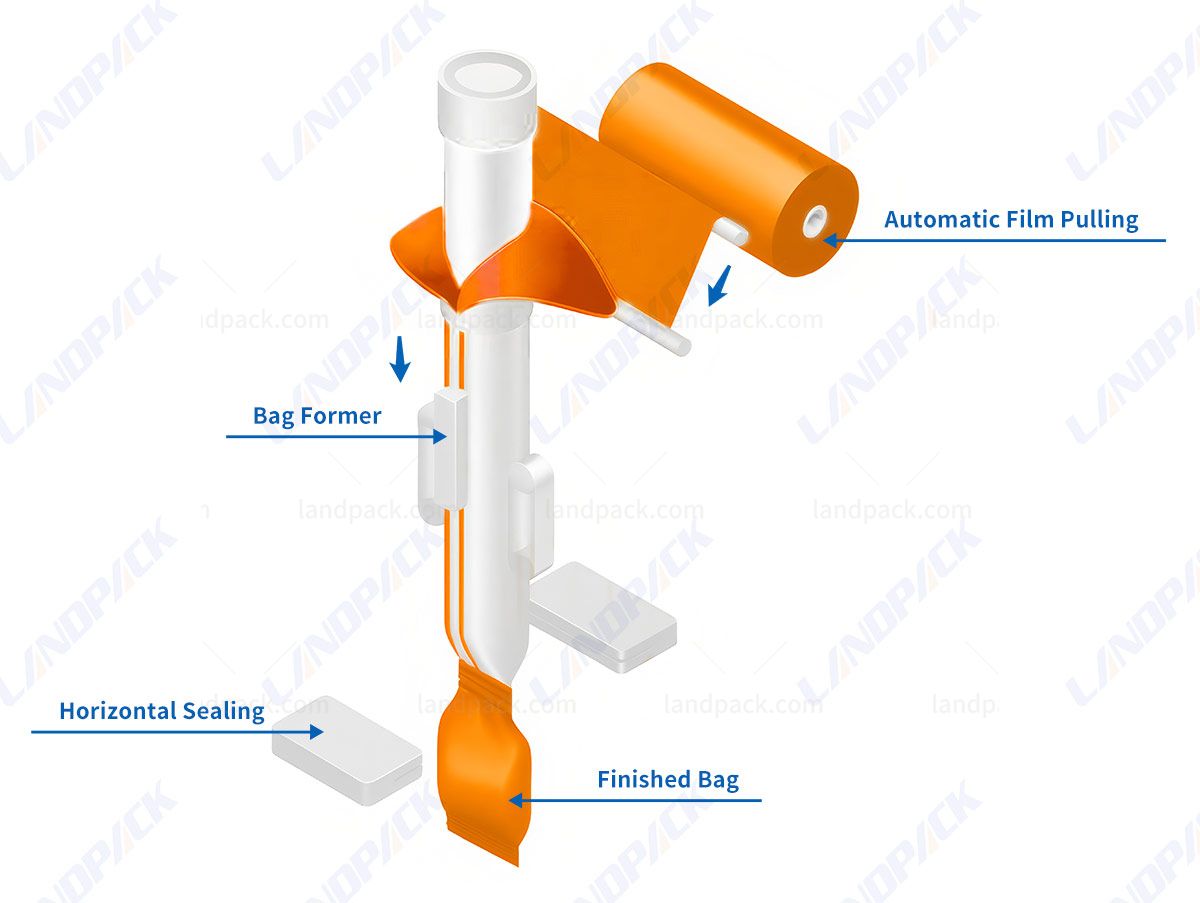

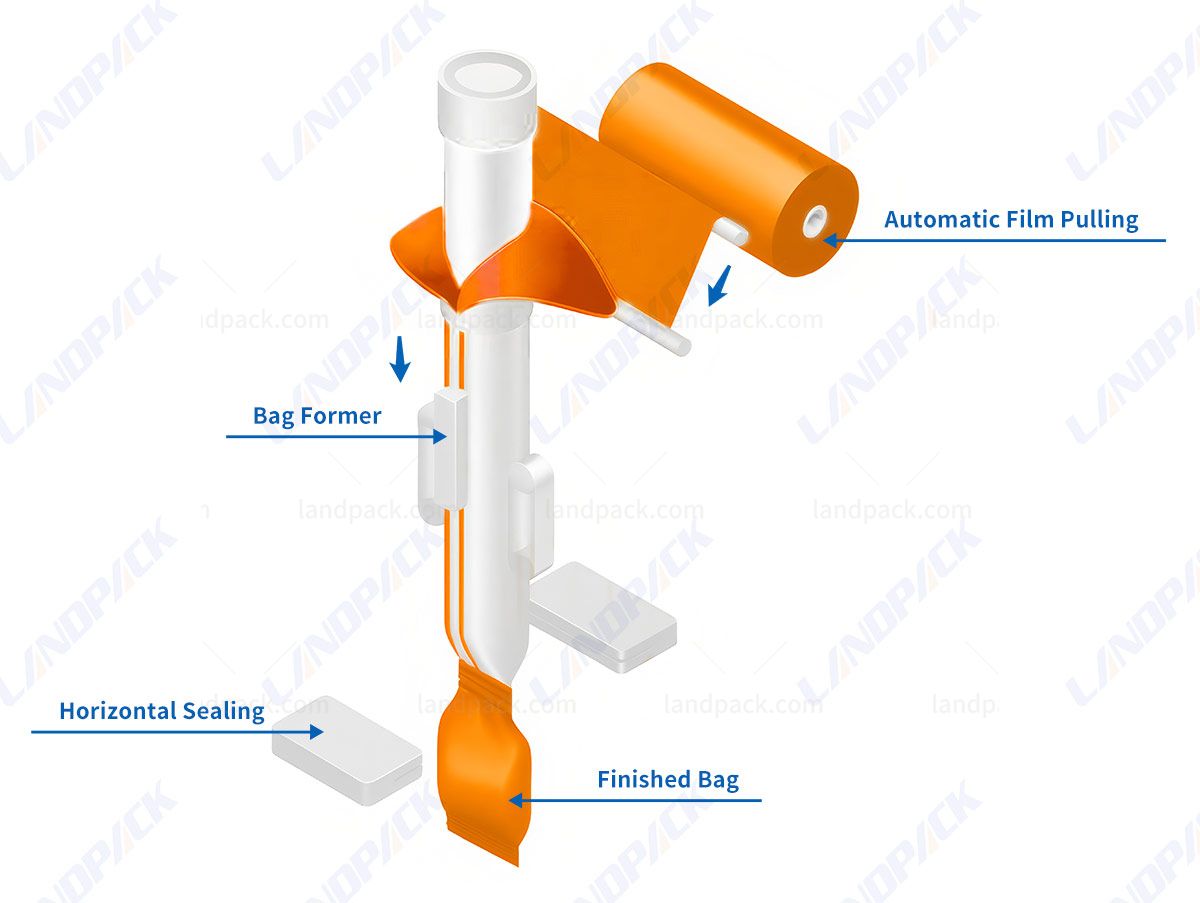

Workflow:

1. Automatic Film Pulling (Film Feeding) The packaging film is automatically unwound from the film roll and fed downwards into the machine.

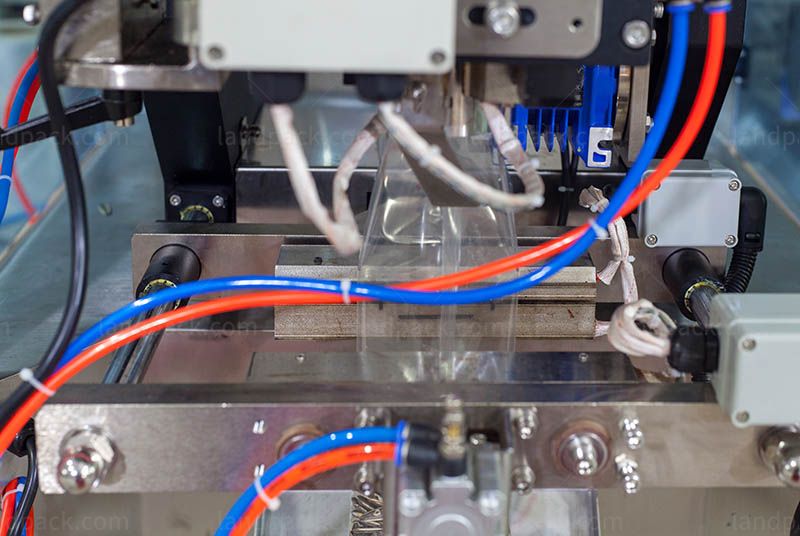

2. Bag Forming The flat film passes over the Bag Former (forming tube), where it is shaped into a cylindrical tube and the vertical seam is sealed (implied).

3. Horizontal Sealing The horizontal sealing jaws close to create the bottom seal of the current bag (and simultaneously the top seal of the previously filled bag).

4. Finished Bag The completely sealed package is then cut and discharged from the machine.