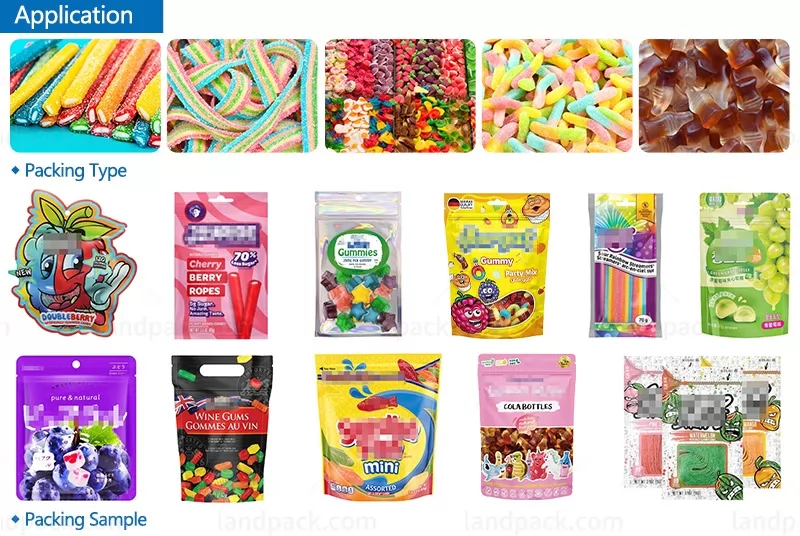

Application:

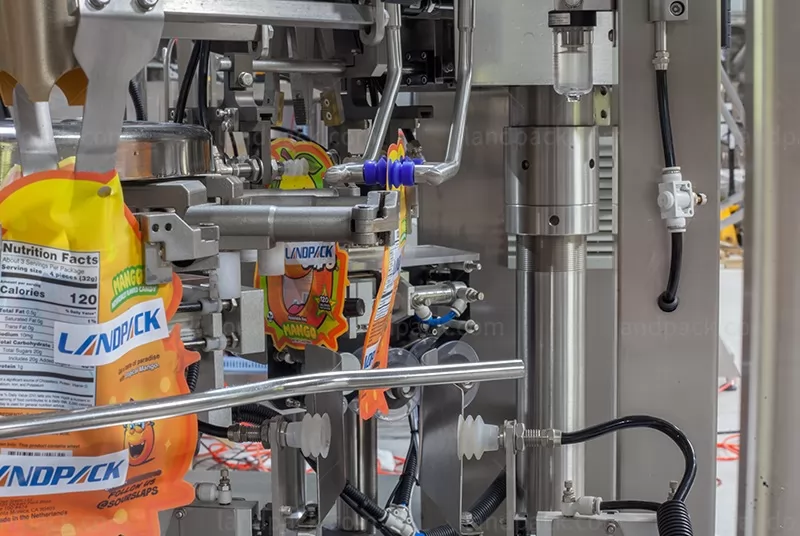

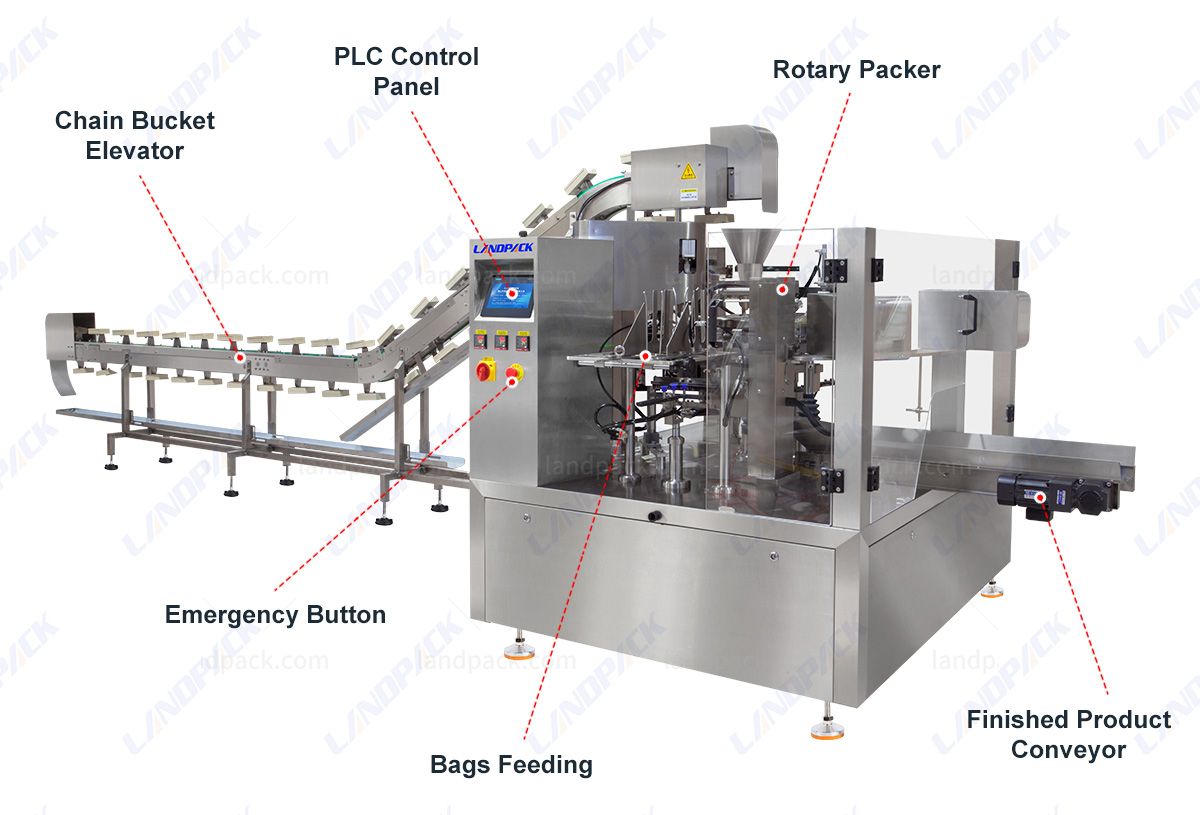

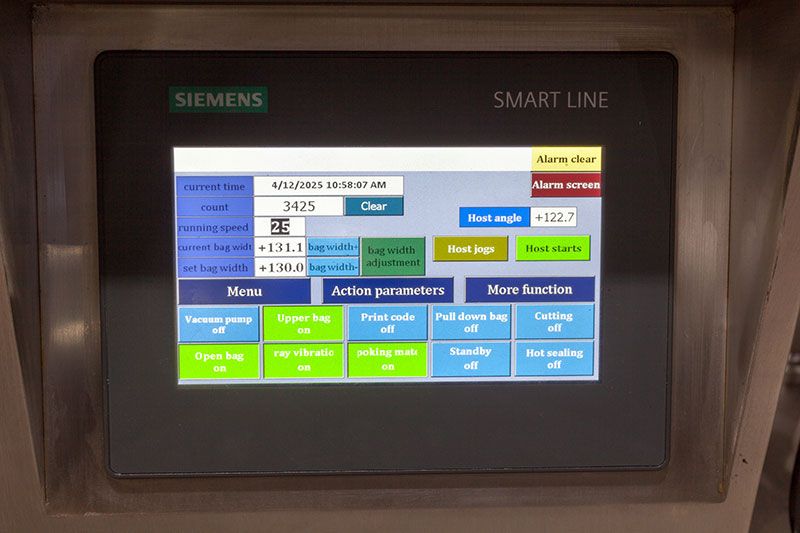

The Gummy Candy Packaging Machine Rotary Pouch Filling Machine is designed for high-speed and accurate packaging of various gummy and jelly products. It is ideal for confectionery factories, nutritional gummy producers, and food supplement manufacturers seeking a reliable pouch packaging solution. This gummy packaging machine can pack up to 60 bags/min, ensuring high productivity while maintaining excellent sealing quality.

Package Type:

The Gummy Candy Packaging Machine Rotary Pouch Filling Machine is compatible with a wide range of pre-made pouch styles, offering flexibility for different market needs and product presentations. It supports stand-up pouches, M-shape pouches, flat pouches, and zipper bags, ensuring each gummy product is perfectly sealed and visually appealing on the shelf.

Suitable Products:

The Gummy Candy Packaging Machine Rotary Pouch Filling Machine is specially designed for packing all types of gummy candies, jelly sweets, and chewable vitamins. This gummy packaging machine uses pre-made stand-up pouches or zipper bags to deliver clean, attractive, and moisture-proof packages.

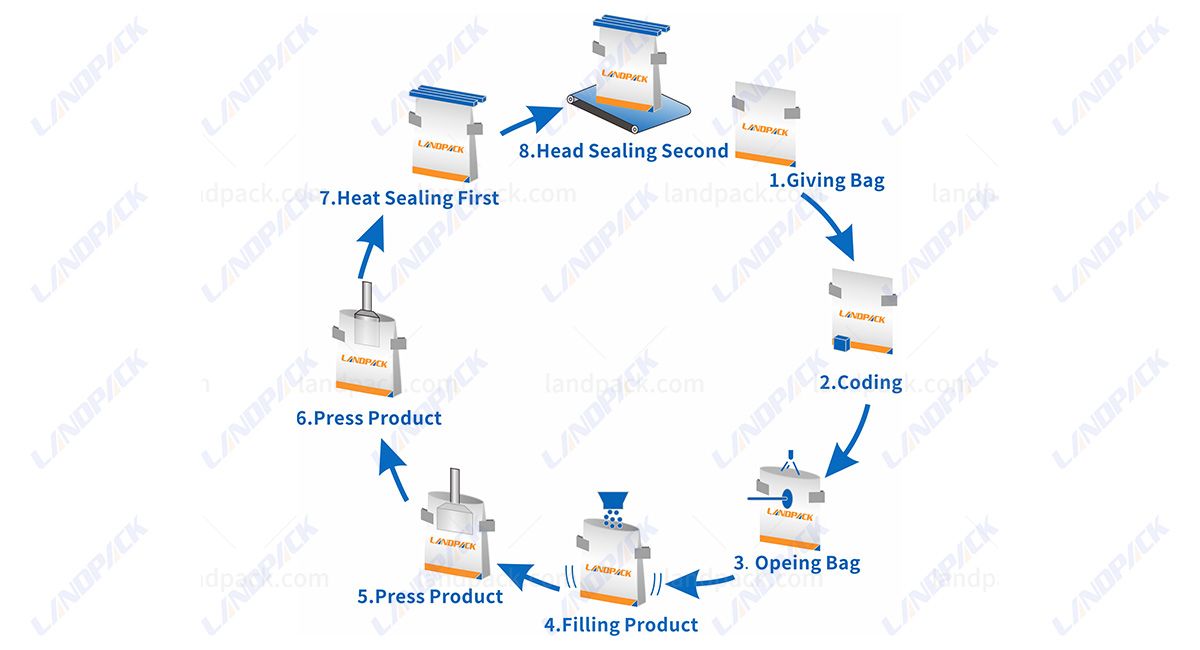

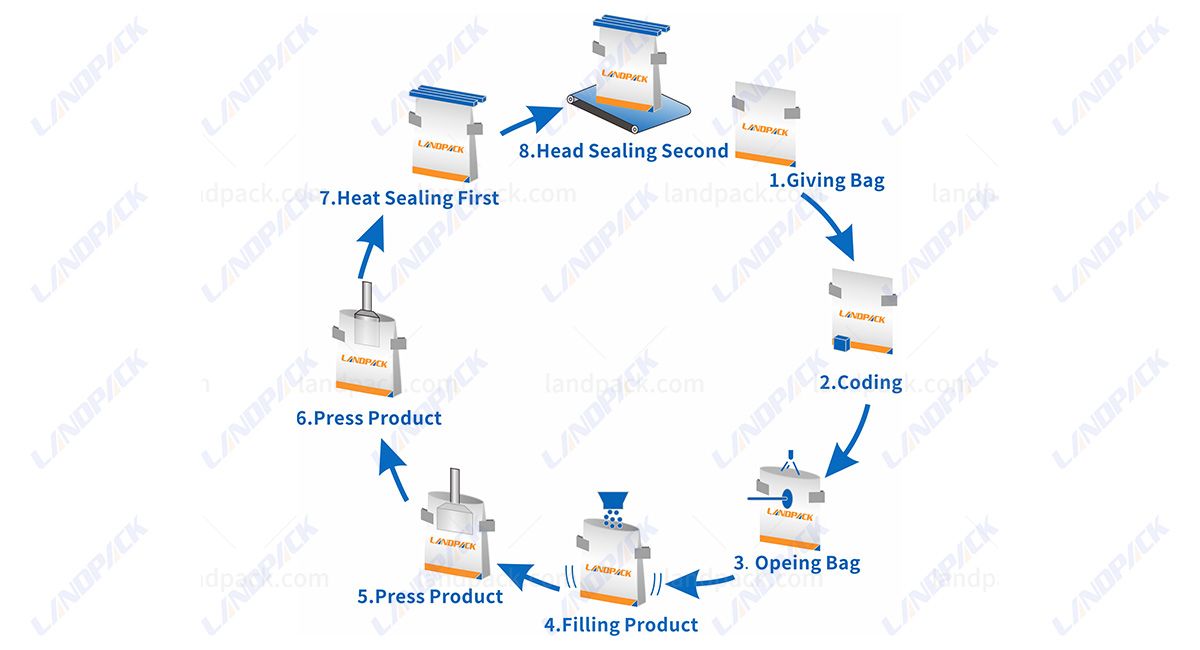

Workflow:

1. Giving Bag: The system automatically picks up pre-made pouches and places them accurately onto the rotary station for filling.

2. Coding: Date, batch number, or production information is printed on each pouch for clear product tracking.

3. Opening Bag: The pouch is gently opened using vacuum suction to prepare for gummy filling.

4. Filling Product: Gummies are precisely weighed and filled into each pouch with high accuracy and minimal product loss.

5. Press Product (First): The filled pouches are leveled to ensure gummies are evenly settled before sealing.

6. Press Product (Second): A second pressing step makes the pouch flat and ready for sealing, improving the final appearance.

7. Heat Sealing First: The pouch's top is heat-sealed tightly to prevent air or moisture from entering.

8. Head Sealing Second: The final sealing ensures complete airtight protection and a professional, attractive finish.