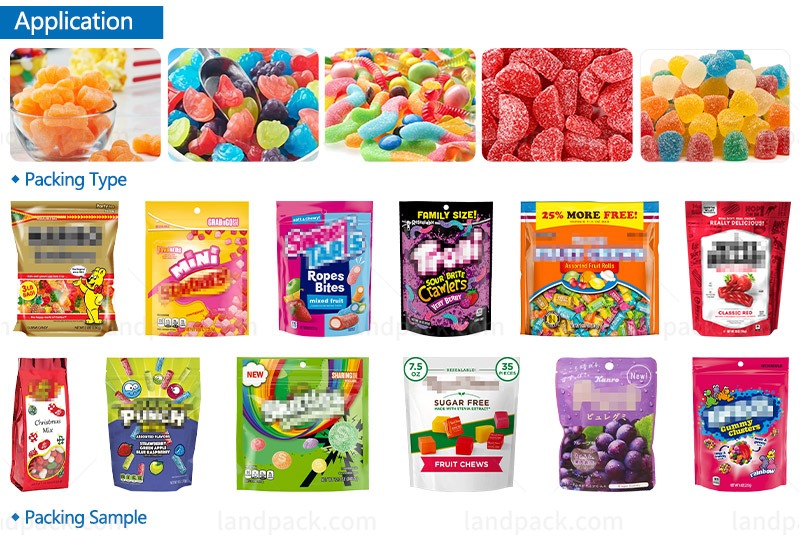

Application:

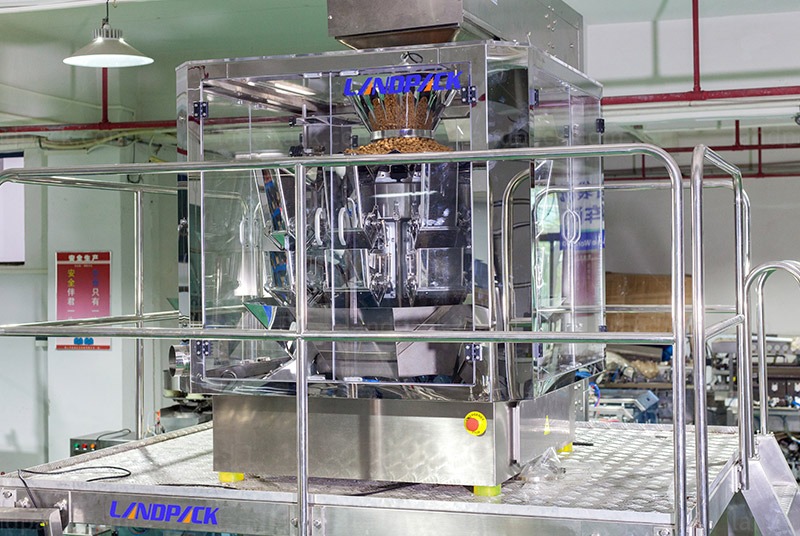

The GP-210A Horizontal Pouch Packing Machine is perfectly suited for packing gummy candies and jelly products. It provides precise dosing and gentle handling to maintain the gummies’ shape, texture, and freshness. Compatible with various premade pouch types such as stand-up pouch, zipper pouch, and flat pouches, it ensures excellent sealing performance and an appealing presentation.

This machine is ideal for fruit gummies, vitamin gummies, collagen gummies, and other chewy confectioneries. Its hygienic design, stable operation, and high-speed performance make it an excellent choice for confectionery manufacturers seeking efficient, reliable, and attractive gummy packaging solutions.

Package Type:

It supports multiple pouch formats, including stand-up pouches, zipper pouches, flat pouches, and spouted pouches. These flexible packaging types are ideal for gummy candies, offering excellent sealing integrity, product visibility, and portability.

Suitable Products:

Horizontal Pouch Packing Machine is specially designed for packaging gummy candies such as fruit gummies, vitamin gummies, and functional gummies. It features precise servo-driven filling to ensure accurate weight control and clean operation without product damage or sticking.

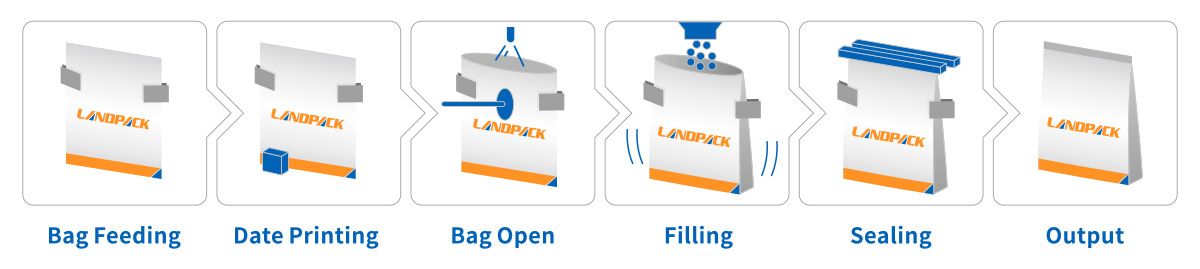

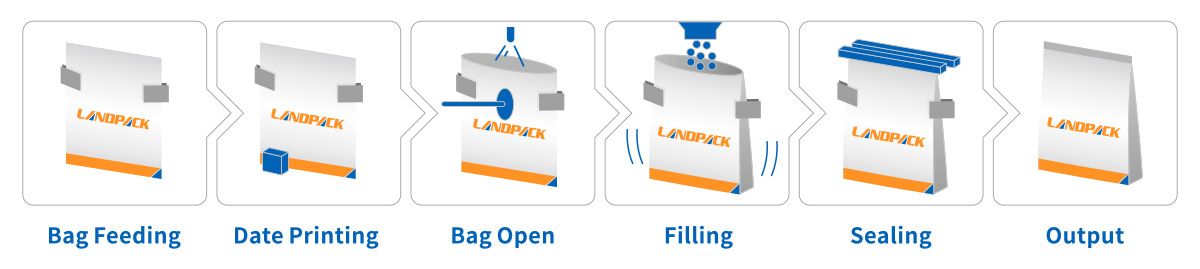

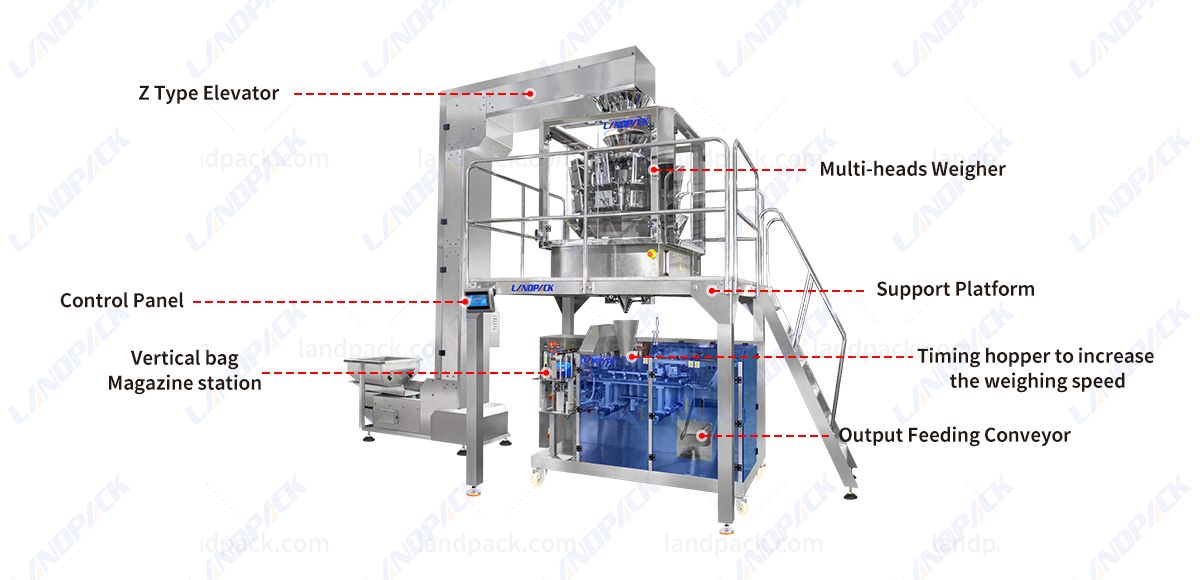

Workflow:

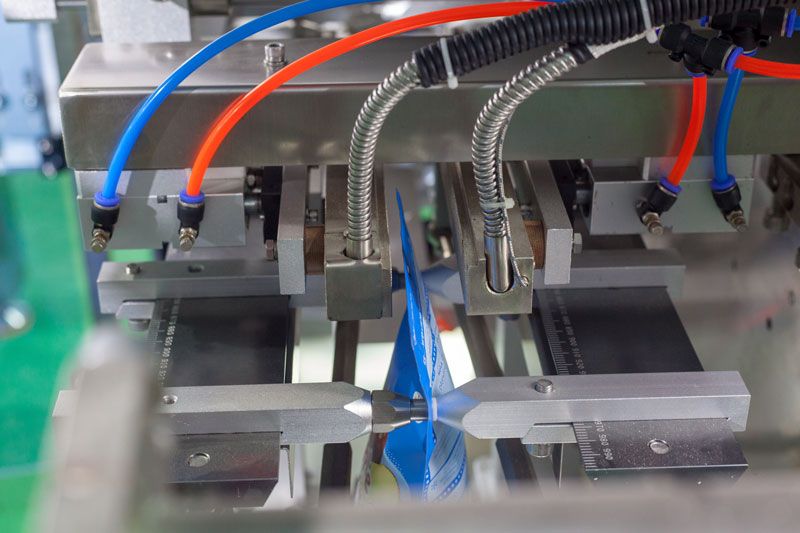

1. Pouch Feeding

2. Gummy Conveying

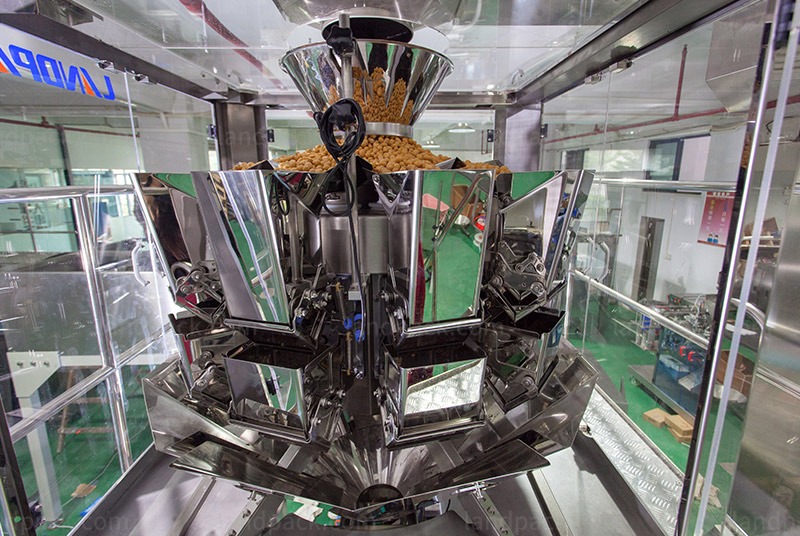

3. Multi-Heads Weighing

4. Filling

5. Sealing

6. Output Collecting