Application:

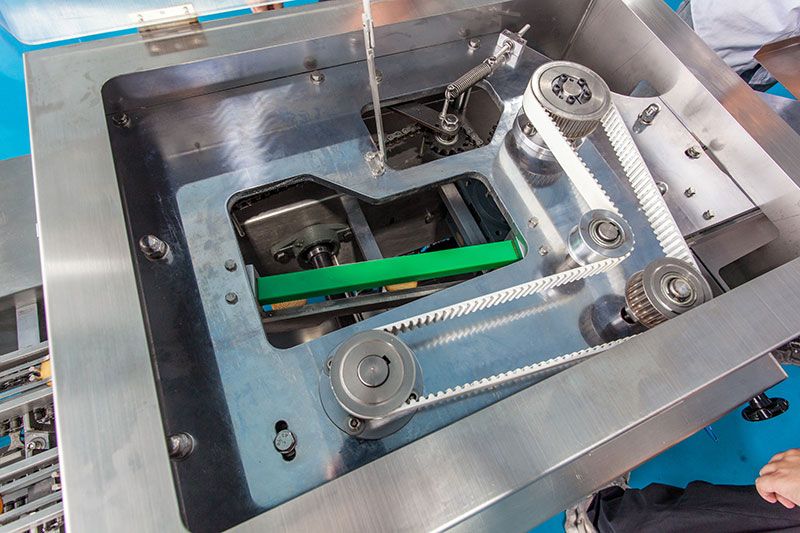

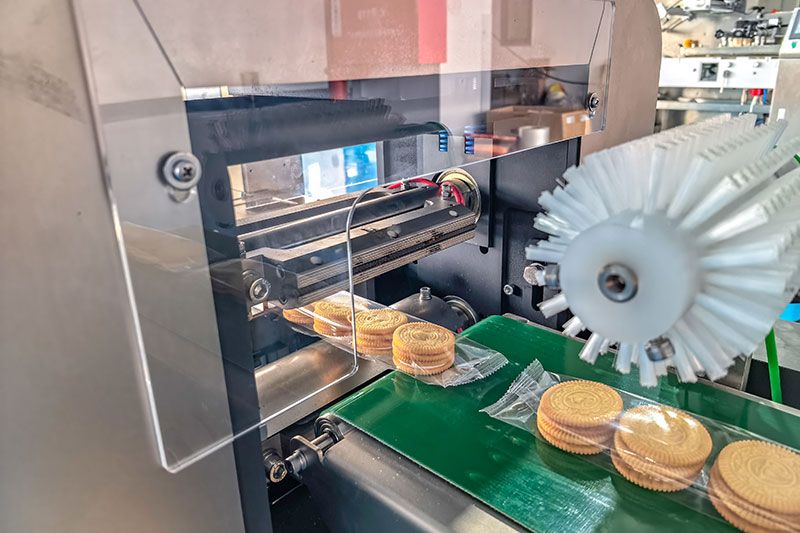

The high-speed pillow packaging machine is designed for sandwich biscuits, cream cookies, and other similar snacks. It features an automated cream injection system, ensuring perfect sandwiching of biscuits. The machine also includes a stacking device that arranges biscuits in two layers for efficient packaging. With the ability to fill cream at 1200 biscuits per minute and a packaging speed of up to 230 packs per minute, this solution is ideal for large-scale production lines demanding high efficiency and product quality.

Suitable Industry:

The sandwich biscuit pillow packaging machine is specially designed for cream-filled biscuits and cookies. Equipped with an automated cream injection system and a stacking device for two-layer arrangement, it ensures precise sandwiching and efficient packaging of products like chocolate biscuits, wafer cookies, and cream-filled crackers.

* Snack: Sandwich Biscuits, Cream Cookies, Chocolate-Coated Wafers, energy bars, etc.

* Bakery Products: Layered Cakes with Cream, Pastries with Fillings, Swiss Rolls, Muffins with Cream Centers, etc.

* Instant Food: Instant Noodle, Rice Crackers, Ready-to-Eat Flatbreads, Snack Pies,etc.

Packaging Style:

This high-speed packing and feeding line is suitable for packing back sealing bags, pillow bags with or without easy tear.

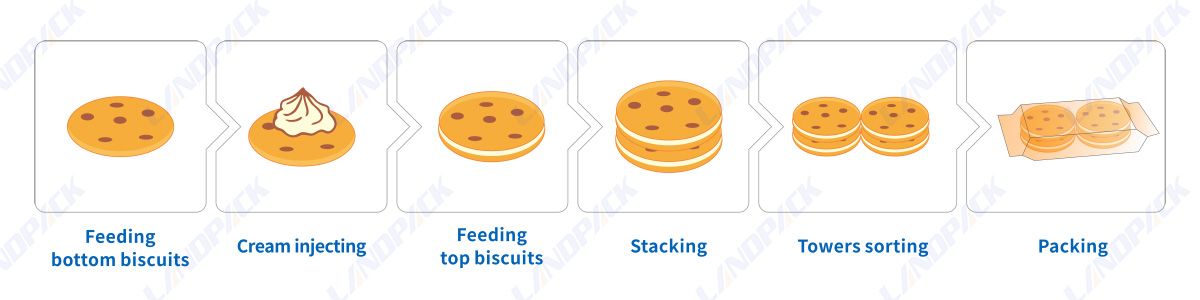

Biscuit Sandwich Production Process:

* Bottom Biscuit Feeding – The lower biscuits are precisely arranged on the conveyor line.

* Cream Filling – A controlled injection system deposits the cream evenly onto each biscuit.

* Top Biscuit Placement – Upper biscuits are placed to create uniform sandwich biscuits.

* Stacking Process – Finished sandwiches are stacked into single or double layers.

* Row Sorting – Stacked biscuits are aligned and organized for consistent flow.

* Final Packaging – Biscuit sandwiches are wrapped, sealed, and delivered as ready-to-sell products.