Application:

It precisely sort, counts and packs biscuits and other cookies into bags, ensuring uniform portions and minimal damage to the product. Ideal for many products, including sandwich biscuits butter cookies with cream, cream-filled cookies crackers, as well as smaller pastries.

Suitable Industry:

This machine has been specifically designed to count, sort and packing a broad assortment of cookies and pastries. It is used extensively in confectionery and bakery industries, handling goods in a variety of shapes and flavors, as well as fillings, with great accuracy and efficacy. Here are some typical applications and the kinds of products:

* Biscuits & Cookies:

Sandwich biscuits, Cream-filled cookies, Digestive biscuits, Butter cookies, Chocolate chip cookies

* Pastries & Bakery Products:

Puff pastries, Swiss rolls, Mini cakes, Muffins, Egg rolls

* Snack Foods:

Crackers, Wafers, Rice cakes, Energy bars, Granola snacks

* Confectionery Items:

Candy bars, Chocolate pieces, Marshmallow treats, Nougat bars

Packaging Style:

This high-speed biscuit feeding packing line is suitable for packing back sealing bags, pillow bags with or without easy tear.

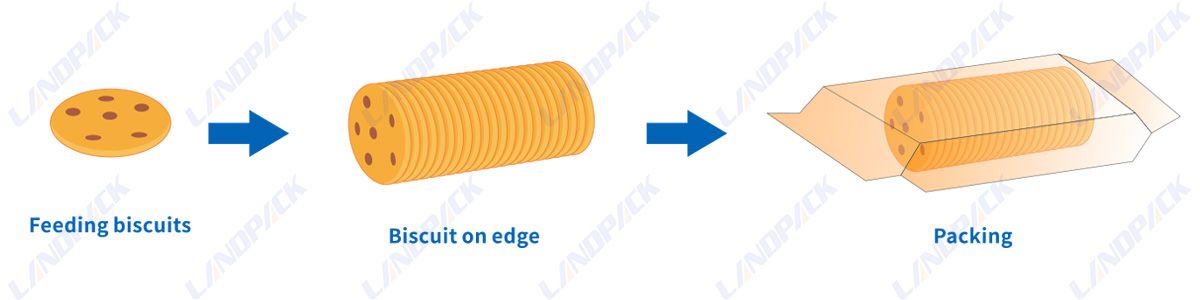

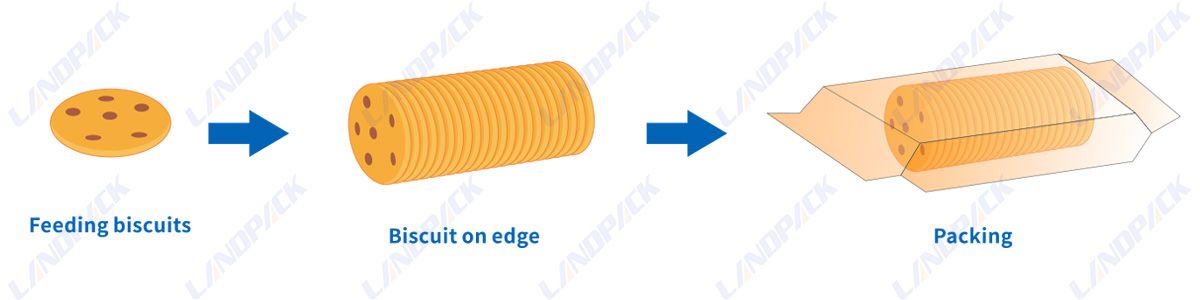

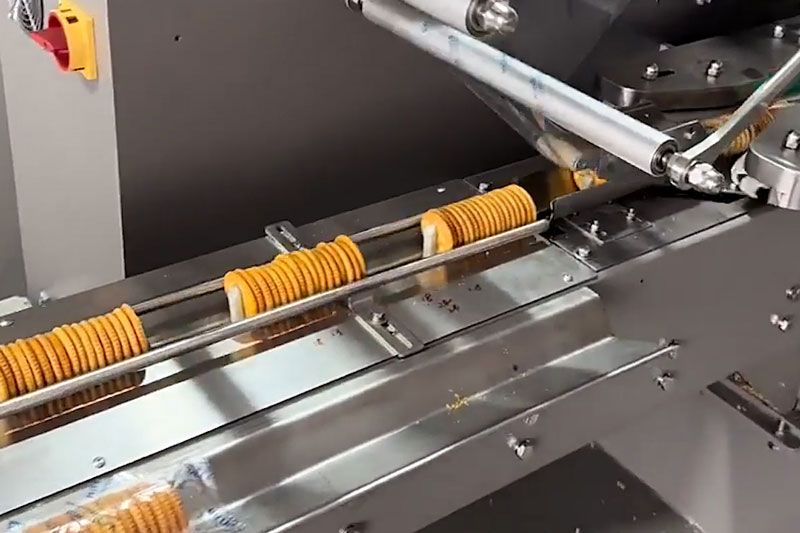

Biscuit Feeding Packing Line Production Process:

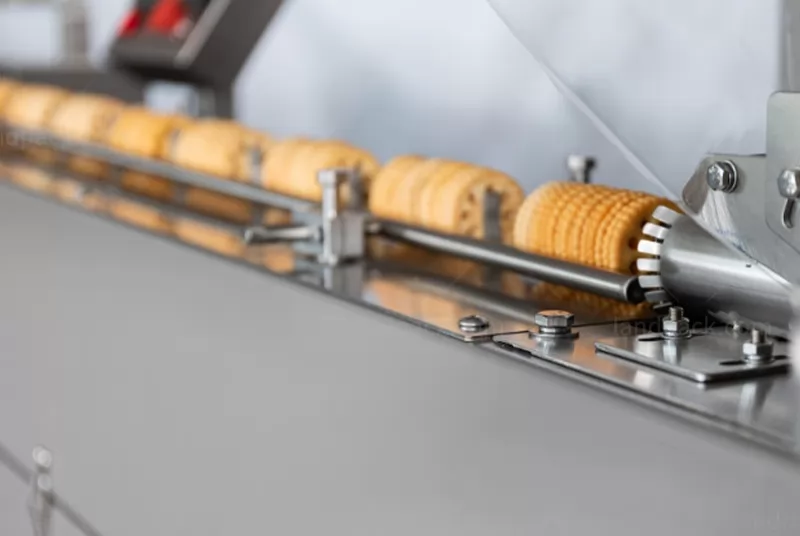

* Product Loading – Biscuits are delivered first from the line of production onto the conveyor for feeding, where they are positioned smoothly to ensure stability and constant flow for next steps.

* Counting & Sorting – The system counts every biscuit precisely, and then arranges them in rows so that every bite is precise and uniform.

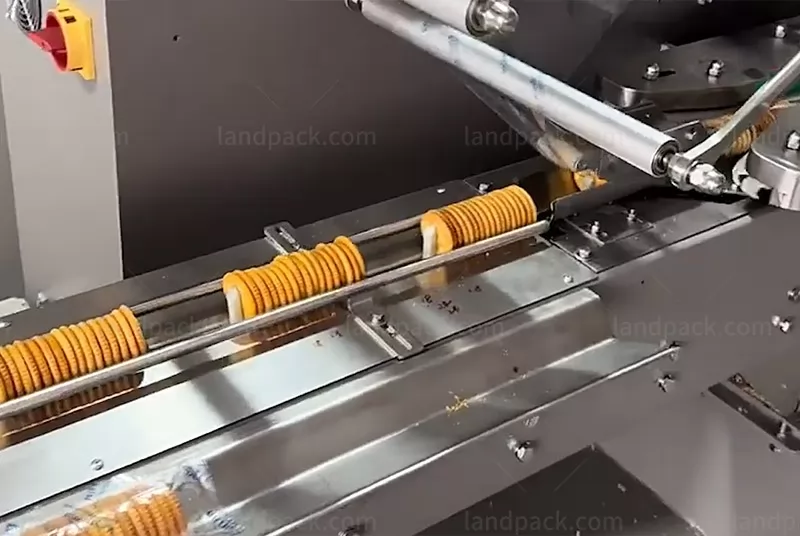

* Film Feeding & Bag Forming – In the meantime packaging film is pulled through the machine, then shaped into pillow-type bags, and then shaped to hold the various biscuits.

* Biscuit Insertion – The biscuits that have been counted are gently placed in the open bags, handled with care to prevent breaking, ensuring that there are the right quantities in each pack.

* Sealing & Cutting – Once the biscuits are in the bags, they are sealed. They are then cut into individual packages, each one being the same dimensions and quality.

* Finished Product Discharge – Finally, the packed items are discharged onto the conveyors, ready for transfer or collection, seamlessly linking to the following stage of packaging.