Application:

High-speed automatic biscuit packing machine designed for bakery products, offering precise wrapping and stable performance at up to 200 bags/min. Ideal for efficient and hygienic packaging of various baked goods.

Suitable Industry:

Our horizontal flow wrapping machine is highly versatile and suitable for packaging a wide range of products across multiple industries:

Snacks & Confectionery

Biscuits, Chocolate bars, Candy, Chips

Bakery & Pastry

Bread, Cakes, Cookies, Pastries

Daily Necessities

Soap, wet wipes, small hardware items, medical supplies

Packaging Style:

This automatic biscuit packing machine is suitable for packing back sealing bags, pillow bags, linked bags with or without easy tear.

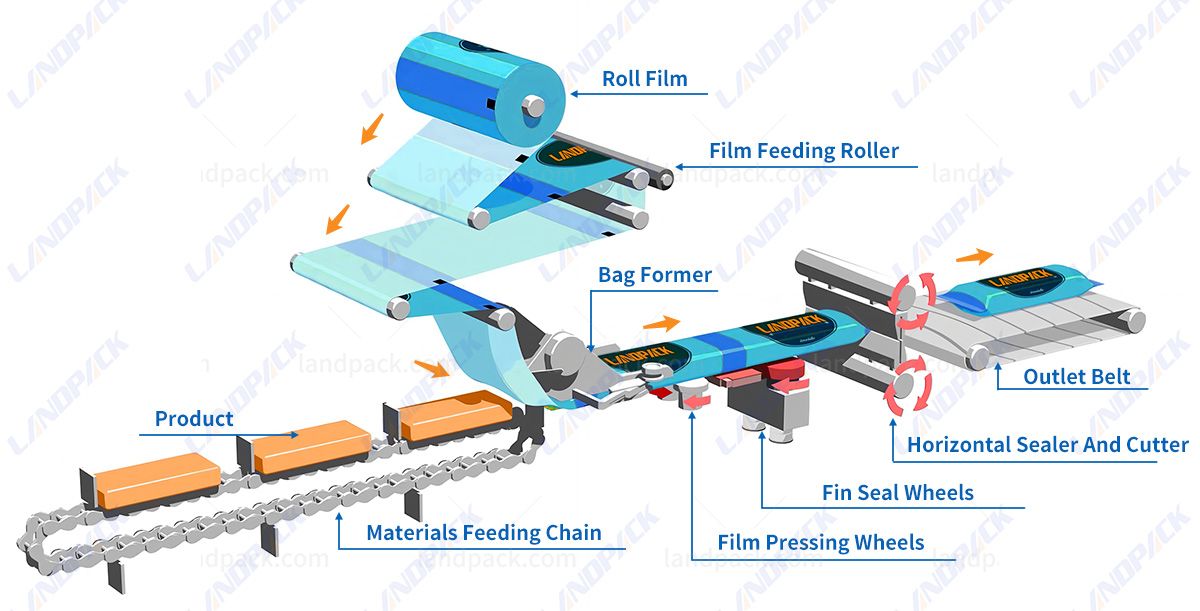

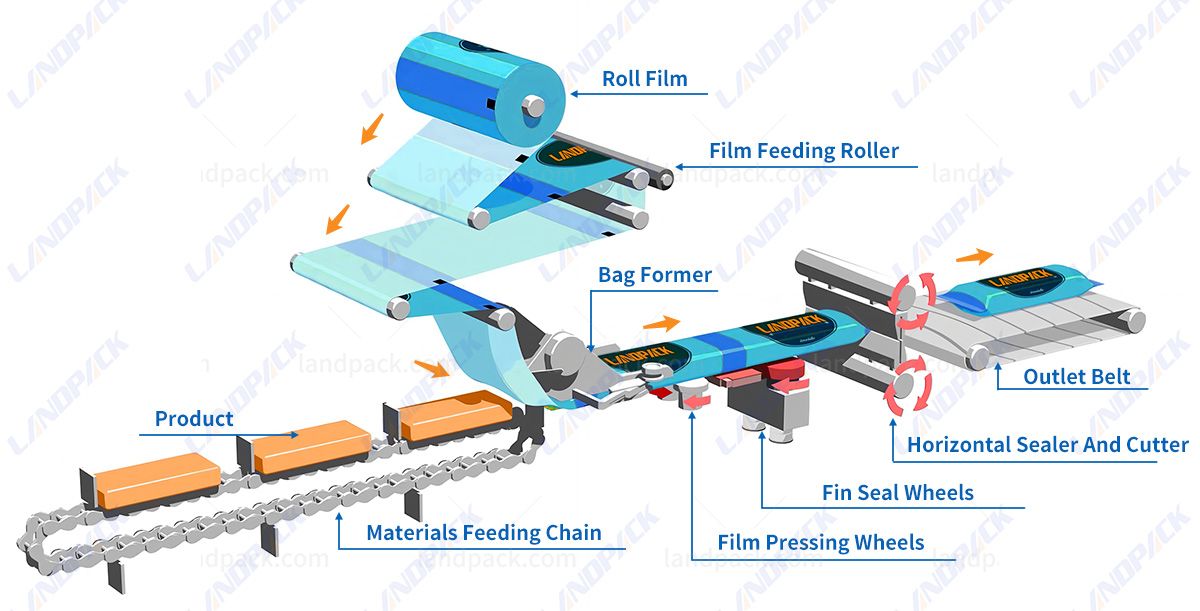

How the Biscuit Packing Machine Works?

* Product Feeding: Products are placed on the materials feeding chain, which moves them forward in a straight line toward the packaging area.

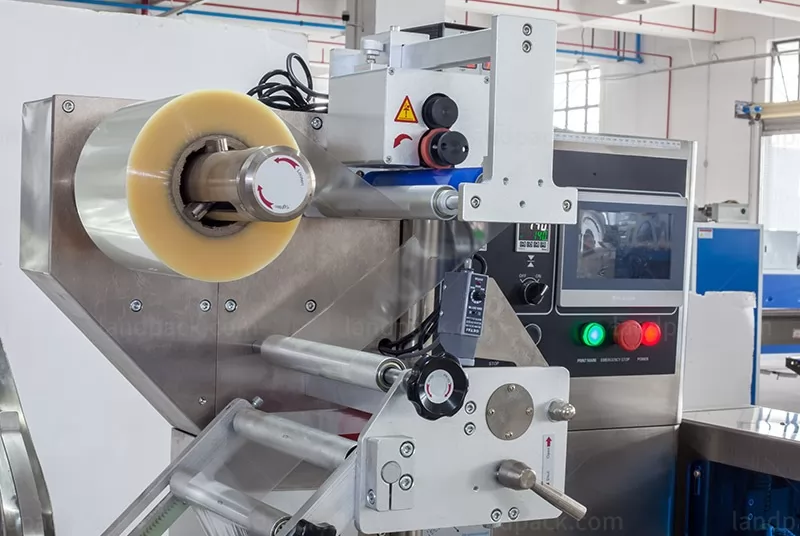

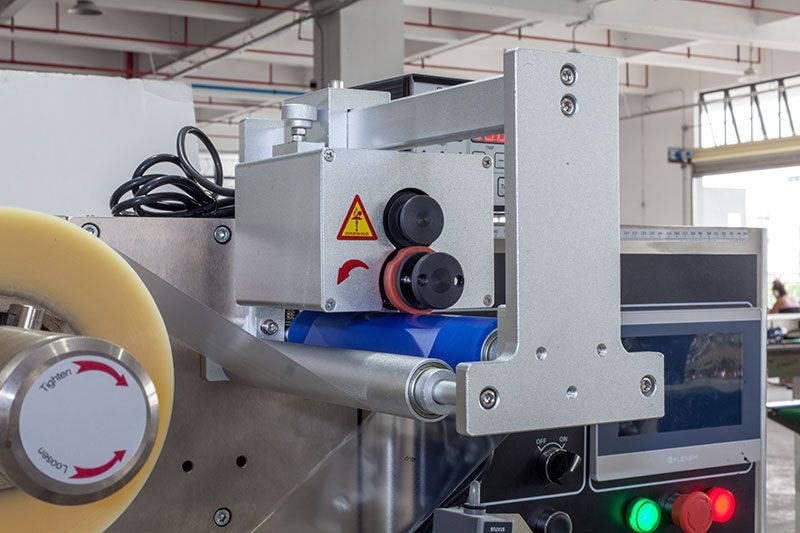

* Film Feeding: A roll of packaging film is loaded on top. The film is pulled down smoothly through film feeding rollers to ensure it stays flat and aligned.

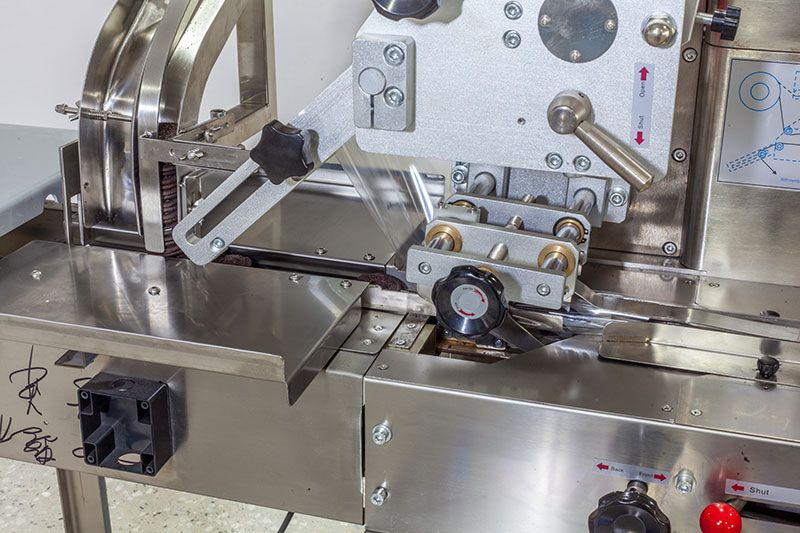

* Bag Forming: The film passes through the bag former, which folds it around the product to create a tube-shaped bag.

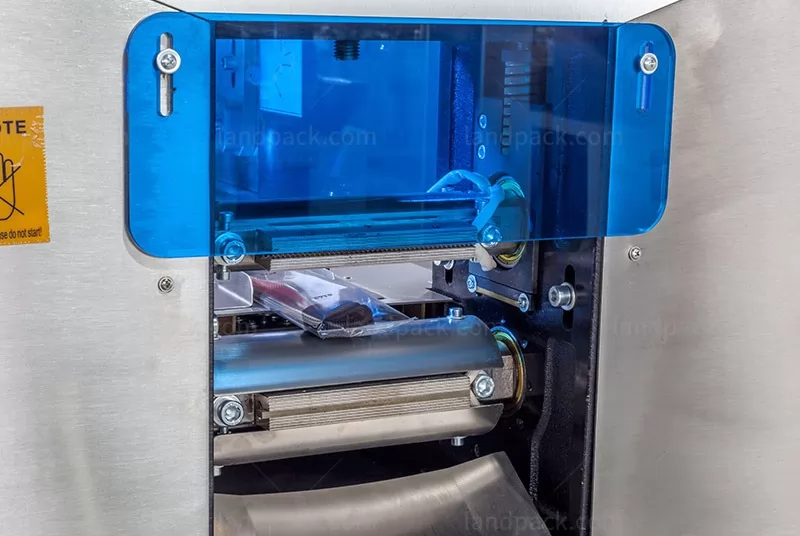

* Fin Sealing: Fin seal wheels and film pressing wheels seal the film along the bottom of the bag to close it tightly around the product.

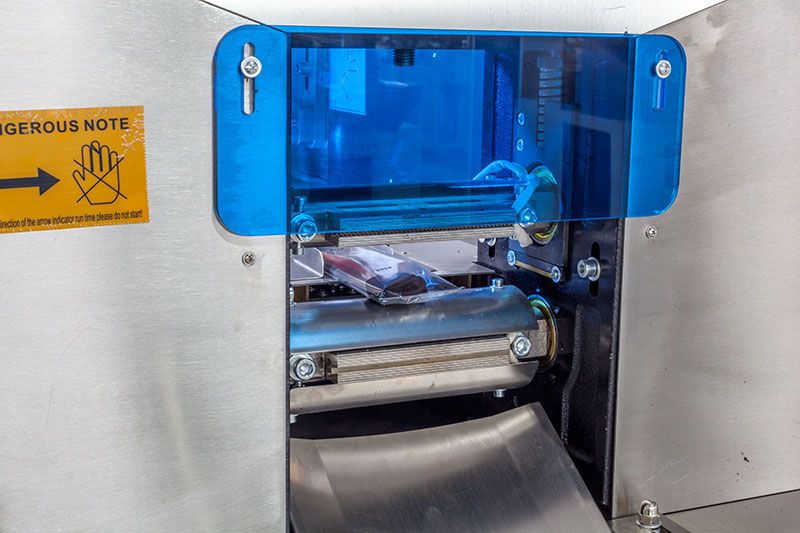

* Cutting and End Sealing: The wrapped products then move to the horizontal sealer and cutter, which seals both ends of the bag and cuts between each product to separate them.

* Finished Product Output: Finally, the individually packaged products come out on the outlet belt, ready for boxing or further handling.